Advantages of Dry Sand Production Line

author:dahua2 time:2022-03-29

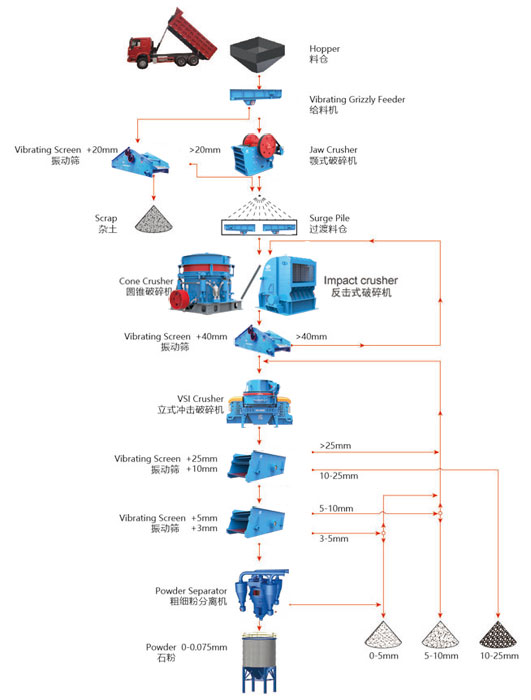

The dry sand production line is free from environmental restrictions, reduces production costs, has better gradation of artificial sand, is more environmentally friendly, and is not limited by water sources and environment.

Taking the raw material below 40mm as an example, the 0-40mm aggregate is transported to the impact crusher by the vibrating feeder and the belt conveyor for crushing, and the impact crushed material is screened by a two-layer vibrating screen. The material is returned to the impact crusher for re-crushing, forming a closed loop. The 3-5mm material can be partially finished according to the discharge requirements, and part of it can be returned to the impact crusher for re-crushing. The material less than 3mm enters the coarse and fine powder separator, and the stone powder of 0-0.075mm is processed. The material of 0.075-3mm and 3-5mm constitutes the finished material pile. Pulse bag filter can be selected according to environmental protection requirements.

Features of dry sand production line:

1. Adjustment of fineness modulus and grading area: Sand making machine and sand and gravel powder separator are equipped with frequency conversion speed control system, which can adjust the production mode according to the characteristics of raw materials, so as to quickly and easily adjust the fineness modulus and stone powder content of machine-made sand , is a high-quality production process.

2. Adjustment of stone powder content (sand equivalent): adjust the stone powder content to the range of use requirements through the sand and gravel powder separator.

3. Good environmental performance: equipped with a special dust removal system, the dust is small, and the noise during operation is less than 90dB.

4. Small footprint, compact production line layout, and high degree of automation: the plane covers an area of 35 meters x 20 meters, and only 2 workers are required for each production shift.

5. The technological process design is scientific and reasonable, which can effectively ensure the quality and output of machine-made sand

6. It can crush medium, high and extra hard materials

7. High automation configuration, minimizing the cost of human resources

8. Excellent gradation of finished sand, adjustable fineness modulus

9. The equipment has low noise and less dust pollution during operation.

Previous Article:No Information

Next Article: What is the Effect of Cone Crusher Crushing Pebbles?