Product Knowledge

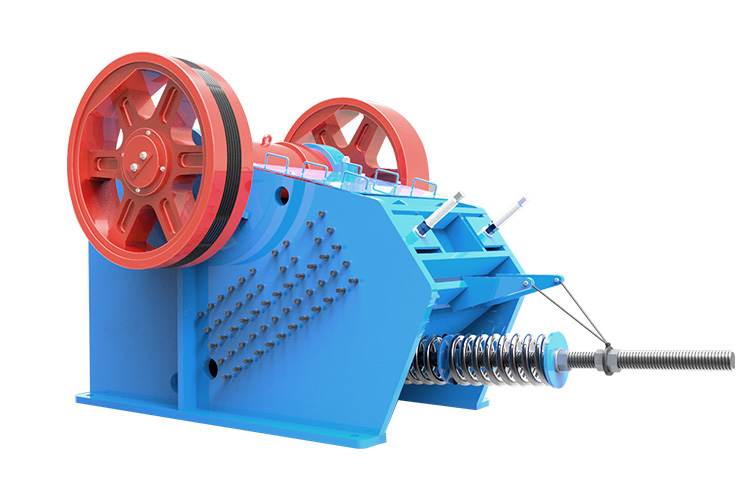

Application and Characteristics of Hydraulic Jaw Crusher in Processing Steel Slag

author:dahua2 time:2024-08-15

PEY Series Hydraulic Protection Jaw Crushers have function of overload protection. It means that when suddenly loaded by blovcks that can not be broken, the machine can instantly auto-unload them by means of its hydraulic protection device, which therefore effectively avoids excessive impact and blocking problem. PEY jaw crusher is often used in the crushing and processing for metallurgical slags.

Crushing efficiency:

1. Strong continuous operation capability: When encountering foreign objects such as large pieces of metal that cannot be crushed in steel slag, the load of the hydraulic cylinder rises sharply, and the hydraulic system is used to automatically retreat and "pass the iron". After passing the iron, it automatically resets. Compared with the traditional jaw crusher, which needs to be shut down for processing and then restarted to resume operation when encountering problems such as stuck steel, it greatly improves the continuity of operation and thus improves the overall crushing efficiency.

2. High throughput: Its uniquely designed crushing chamber type, reasonable eccentricity, swing frequency and layer compression crushing principle are combined to achieve a larger throughput.

Operation stability:

1. Reduce equipment impact: Since the automatic retreat system avoids the sudden impact force of foreign objects stuck steel on the equipment, it reduces the impact on the equipment's main structure such as the movable jaw, frame, shaft and other key components, the equipment runs more smoothly, reducing the probability of equipment failure and the probability of downtime caused by equipment failure.

2. Balanced force on the movable jaw: The single hydraulic cylinder supported by the hydraulic station will not produce asynchronism like the double hydraulic cylinder, causing the movable jaw to segregate and damage the body.

Maintenance:

1. Reduce maintenance frequency: effectively solve the "steel jam" problem and reduce foreign body impact, so that the replacement frequency of wearing parts such as toggle plate, movable jaw plate, fixed jaw plate, etc. is reduced.

2. Hydraulic system reliability: it can still work effectively under a certain degree of pollution, with strong adaptability, reducing maintenance caused by hydraulic system pollution and other reasons.

Material processing effect

1. Improved material purity: it can automatically discharge foreign matter that cannot be crushed in steel slag, improve the purity of subsequent materials, and facilitate the subsequent deep processing and utilization of crushed steel slag.

2. Particle size uniformity: although it is a coarse and medium crushing equipment, the reasonable design of its crushing action and principle makes the particle size distribution of crushed steel slag relatively concentrated and uniform, which is conducive to the stability and efficiency of subsequent processing operations.

Adaptability

1. Adapt to complex materials: especially suitable for continuous crushing of material flows containing more material obstacles (such as large pieces of scrap steel often mixed in steel slag, metal wrapped in waste slag, etc.) and non-single medium.

2. Environmental adaptability: It can maintain stable crushing performance in some harsh working conditions.

Safety

1. Operator safety: Since the machine can automatically handle unbreakable objects without stopping the machine, it reduces the possibility of operators touching the equipment for troubleshooting and other dangerous operations during the operation of the equipment.

2. Equipment safety: The equipment's built-in overload protection and other functions ensure the safe operation of the equipment itself, avoiding major accidents such as serious damage to the equipment or even scrapping due to overload.

Economic benefits

1. Increase production: Due to continuous operation and high throughput, the output per unit time can be increased, and a large amount of slag can be quickly processed, increasing the output benefits for the enterprise.

2. Reduce costs: The comprehensive cost of slag crushing is comprehensively reduced from aspects such as reduced maintenance costs, extended equipment life, and optimized energy consumption (such as reasonable crushing principles to achieve high output per unit energy consumption).

Previous Article:No Information

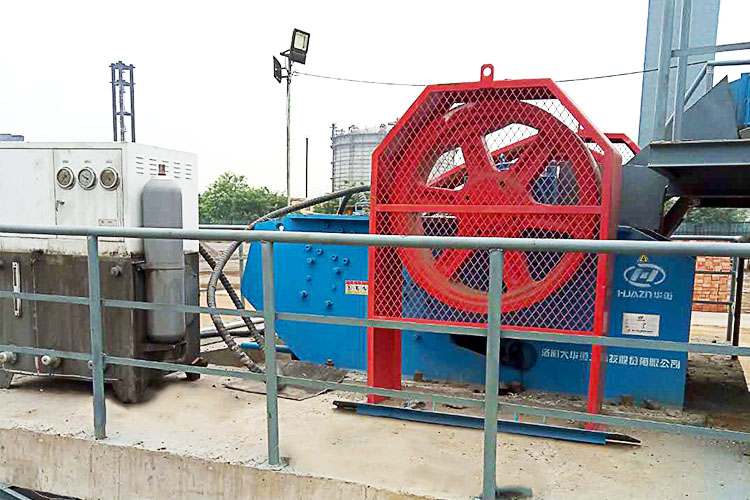

Next Article: The processing capacity of Huazn Hydraulic Cone Crusher