Product Knowledge

Choosing the Right Crusher for Crushing Stone With High Moisture Content

author:dahua2 time:2025-01-09

Mining Crusher is commonly used to crush various brittle materials, medium-hard materials, and minerals with low moisture content. Some stones have high moisture content and high viscosity,such as coal and clay. So what kind of crusher should be used for this kind of wet materials? The following Dahua engineers recommends three types of crushers suitable for processing wet materials.

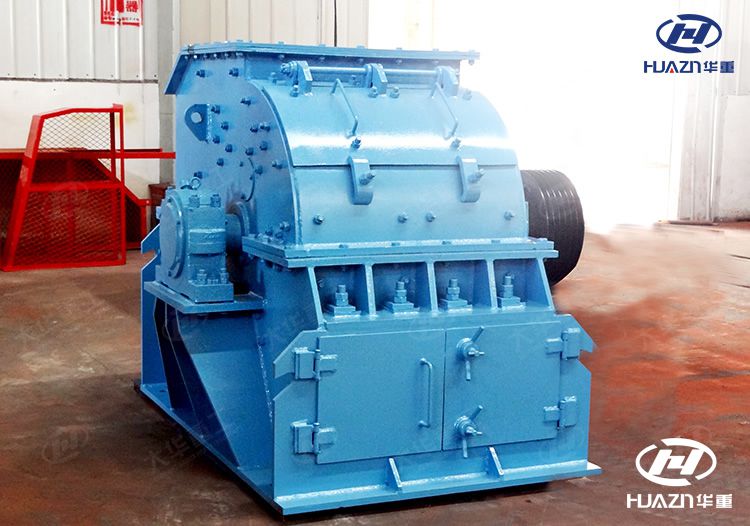

1. PC hammer crusher

The PC series hammer crusher mainly relies on the high-speed rotating hammer body and the material collision surface to crush the material. It has the characteristics of simple structure, large crushing ratio, and high production efficiency. It can be crushed in dry and wet forms. The equipment can adjust the grate gap according to user requirements and change the discharge particle size to meet the different needs of different users.

2. PFQ impact crusher

The PFQ series vortex strong impact crusher is designed with a unique vortex crushing chamber and P, S, and T three-stage crushing zones, which can achieve powerful vortex flow impact crushing. Therefore, the equipment has a larger feed particle size, higher production capacity, and the product particle size can be adjusted and controlled. There is no grate at the bottom of the impact crusher. The crushed material is discharged directly from the bottom of the crushing chamber and is not easy to be blocked.

3. PFL vertical compound crusher

PFL vertical compound crusher is a new type of fine crushing and coarse grinding product. This product has both impact and grinding crushing mechanisms. Our company presided over the drafting of the national industry standard for this product. This series of products can achieve more crushing and less grinding, and is an ideal fine crushing equipment for energy saving and consumption reduction.

The compound crusher has a large crushing ratio and high crushing moisture content. It is ideal for processing materials with high moisture content. The discharge particle size can be adjusted arbitrarily, and there is no screen bar setting. It will not block the processing of materials with high moisture content and sediment.

In addition to the choice of crushing equipment, if you want efficient output, we need to pre-treat the stone before crushing, such as screening, washing, etc., to remove impurities and parts that are not suitable for crushing, reduce humidity and viscosity, and thus improve crushing efficiency and uniformity; you can also use a pre-drying system to reduce the moisture content of the stone to prevent it from adhering to the inside of the equipment during the crushing process, reducing blockage and wear.

Previous Article:No Information

Next Article: How to Choose the Secondary Crusher For Crushing River Pebbles?