The Differences Between Cone Crusher and Impact Crusher

author:dahua2 time:2022-09-08

Cone crusher and impact crusher are both secondary fine crushing equipment, and their differences are described as follows:

1. The different working principle:

Cone crusher adopts the principle of lamination crushing

During operation, the particles and the lining plate, the particles and the particles are kneaded with each other, so that the flat and long particles are broken along their weak parts. With less content and good grain shape, it can meet the special grain shape requirements of hydropower, urban construction, highway, railway and other industries.

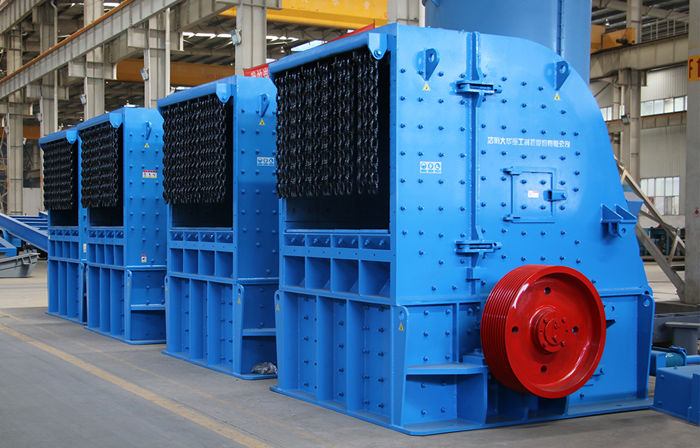

Impact crusher uses the principle of impact crushing

During operation, driven by the motor, the rotor rotates at a high speed. When the material enters the blow hammer effect area, it collides with the blow hammer on the rotor and breaks, and then is thrown to the counterattack equipment to be broken again, and then bounces back from the counterattack liner. To the blow hammer effect area to break from scratch, repeat this process until the material is broken to the desired particle size.

2. The different discharge particle types:

The impact crusher not only crushes the material, but also has a certain function of shaping the particles. The distribution is more reasonable and the grain shape is beautiful.

In contrast, although the crushing effect of the cone crusher is good, it is slightly inferior to the impact crusher in the shaping of the discharged particles.

3. Different wear resistance:

The impact crusher has many wearing parts, such as hammer head, impact plate and other parts need to be replaced frequently, so the equipment wear and depreciation is faster, and the later operation and maintenance costs are higher.

The wearing parts of cone crusher have a relatively long life, and there is no need to replace the parts frequently, so the loss and depreciation of the equipment are slow, and the later operation and maintenance costs are low.

4. Different capacity sizes:

Impact crusher adopts a solid heavy-duty rotor structure, which improves the handling capacity and crushing ratio of materials, thereby increasing its crushing capacity. In general, the production capacity of impact crusher is between 50-1200t/h.

Cone crusher combines high crushing cavity type and high crushing frequency well, and adopts PLC+ touch screen automatic control system, which effectively improves its processing capacity of materials. In general, the capacity of cone crusher is between 45-2188t/h.

Previous Article:No Information

Next Article: Hammer Crusher VS Impact Crusher ,Which Crusher is Better for Secondary Crushing?