Product Knowledge

Types of Crushers for Mineral Processing

author:dahua2 time:2024-05-22

Crushing Process in Mineral Processing

In the mineral processing industry, the crushing process is a fundamental step that plays a crucial role in extracting valuable minerals from the ore. The primary objective of the mineral crushing process is to reduce the size of the ore particles while maintaining the integrity of the mineral as much as possible. By breaking down the larger rocks into smaller fragments, the surface area of the ore increases, allowing for better exposure of the valuable minerals to subsequent processing steps, such as grinding, flotation, or leaching.

The crushing process can be divided into several stages, depending on the final product’s desired size and the ore’s characteristics. The primary crushing stage is typically the first step in the process and involves the initial reduction of the ore size. This is followed by secondary and, in some cases, tertiary crushing stages to further reduce the ore size to the desired level.

Types of Crushers for Mineral Processing

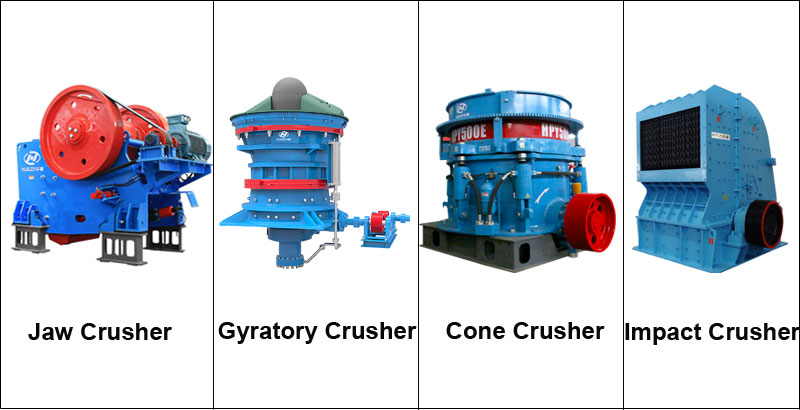

Different crushers are used in the ore crushing process, depending on the nature of the ore and the required product size. Commonly used crushers include jaw crushers, gyratory crushers, cone crushers, and impact crushers. Each crusher type operates differently, applying various forces to break down the ore particles.

Jaw crushers are commonly used for primary crushing and are characterized by their ability to handle large-sized rocks or ore. Gyratory crushers are similar to jaw crushers but have a conical head and a concave surface. They are often used for primary or secondary crushing. Cone crushers are versatile and can be used for primary, secondary, or tertiary crushing. On the other hand, impact crushers involve using impact or striking forces to break down the ore particles.

The selection of the appropriate crusher depends on factors such as the hardness and abrasiveness of the ore, the desired product size, and the operational considerations of the mineral processing plant. Selecting the right crusher to achieve the desired size reduction level and ensure efficient operation of the overall mineral processing circuit is crucial.

Previous Article:Huazn Complete Limestone Crushing Plant Machines

Next Article: Huazn Company: Join Us at 2024 CTT Expo in Moscow, Russia