Product Knowledge

What is the difference between jaw crusher and hammer crusher?

author:dahua2 time:2023-05-11

1. Working principle

Jaw crusher belongs to extrusion crushing. The working part consists of two jaws, one is the fixed jaw (fixed jaw), which is fixed vertically (or the upper end is slightly inclined outward) on the front wall of the machine body, and the other is the movable jaw (moving jaw). Jaw), the position is inclined, and the fixed jaw plate forms large and small crushing chambers (working chambers). The movable jaw performs periodic reciprocating motion on the fixed jaw. When separating, the material enters the crushing cavity, and the finished product is unloaded from the lower part; when approaching, the material between the two jaw plates is squeezed, bent and split.

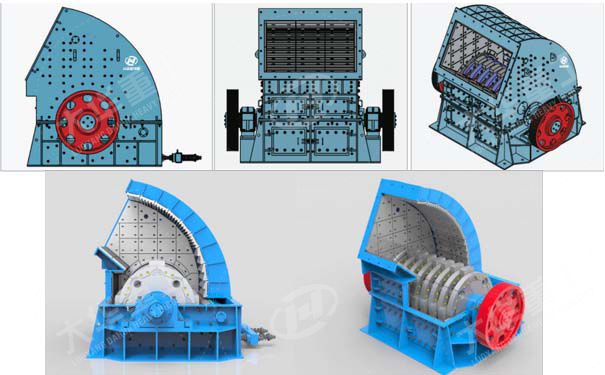

Hammer crusher belongs to impact crushing, which mainly relies on impact energy to complete the operation of crushing materials. When the hammer crusher is working, the motor drives the rotor to rotate at a high speed, and the material enters the crusher chamber evenly. The high-speed rotary hammer impacts, shears, tears and crushes the material. At the same time, the gravity of the material itself makes the material rush from the high-speed rotary hammer into the frame baffle, screen There is a sieve plate at the lower part of the rotor, and the crushed material is smaller than the size of the sieve.

2. Scope of application

Jaw crusher is a kind of coarse crushing equipment, its main function is to crush large stones initially, and it is widely used in the first crushing of crushing production line and sand making production line.

Hammer crusher belongs to medium and fine crushing equipment, which is widely used in secondary crushing.

3. Material type

Jaw crushers are widely used for crushing hard, hard and soft ores and various materials, such as various ores, fluxes, slag, building stones, marble, etc.;

Hammer crusher is widely used in medium and fine crushing of cement, coal preparation, coke, oil shale, chalk, gypsum and other brittle, medium-hard and soft materials; it is suitable for crushing medium-hard and brittle materials such as limestone and coal.

4. Feed size

The feed particle size of the jaw crusher is 125-850mm.

The hammer crusher can directly crush stones up to 2 meters into raw materials. One-time molding, no return material.

5. Capacity

The output of jaw crusher can reach 5-2000 tons per hour.

The output of hammer crusher can reach 80-3000 tons per hour.

Previous Article:No Information

Next Article: What are Advantages of Pebble Cone Crusher?