Granite Processing Plant

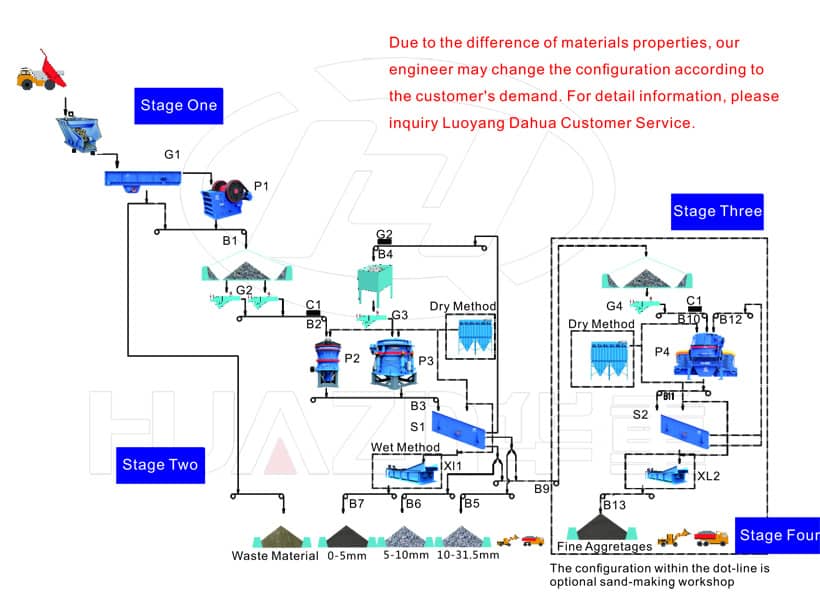

Granite processing contains three procedures, coarse crushing, medium and fine crushing, and shaping stages.

♦ The first stage: Coarse Crushing

The lump granite will evenly go through the vibrating feeder and transport to jaw crusher for coarse crushing. After the separation by the vibrating feeder the crushed material then will be transported to the impact crusher or cone crusher by the belt conveyor for medium or fine crushing.

♦ The second stage: Medium and Fine Crushing

The medium or fine material crushed by impact crusher or cone crusher will be separated by vibrating screen. The material with bigger granularity will be re-sent to impact or cone crusher again.

♦ The third stage: Shaping

The crushed granite will be sent to the sand-making machine for further crushing and re-shaping. If the clean granite is needed, then it could be sent to the sand washing machine for cleaning.

Related Product

Application

Guangxi Sand Making Production Line

Material Processed: Granite Production line

Output: 600t/hour

Equipment Configuration: Vertical Shaft Impact Crusher, Impact Crusher, Jaw Crusher, Sand Washer

Customer Evaluations: Through comparation of other company’s equipment and field trips, the performance and production capacity of Dahua equipment can meet our requirements. The engineer provides us the detailed configuration under the condition of saving money, and we are satisfied with the finished products shape and capacity.

Guangdong Production Line

Material Processed: Granite Production line

Output: 500t/hour

Equipment Configuration: Vertical Impact Crusher, Jaw Crusher, Sand Washer

Customer Evaluations: Dahua production line with reasonable configuration, compact structure. They provide us the optimal solution combining our site situation and economic condition, after commissioning, the company offers free training for the operators. There is no machine blockage or crash.