Cone Crusher Impact Crusher, which one is more cost-effective? Which one has better finished particle size?

author:dahua time:2021-08-13

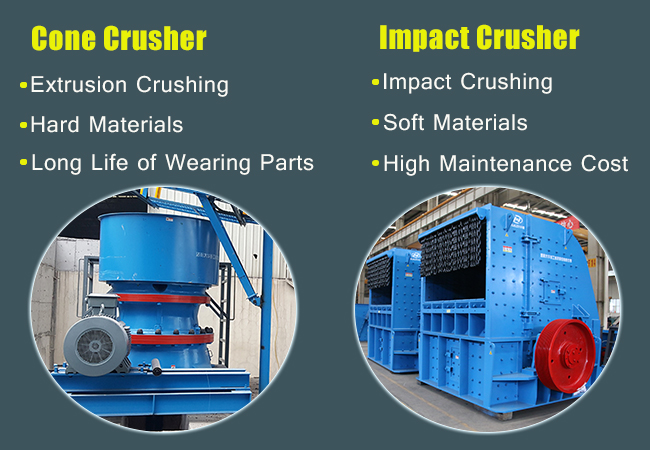

Cone crusher and impact crusher belong to the secondary crushing equipment in the crushing process, which are used to complete the fine crushing operation of all kinds of sand and stone materials. They are the crushing equipment often used by users. So which one is more cost-effective? Which one has better finished particle size? Here Luoyang Dahua, crusher manufacturer will tell you the answer.

I. Which one is more cost-effective? What's the difference between cone crusher and impact crusher?

1. Different working principles

The cone crusher adopts the principle of extrusion crushing. The concave moves to the mantle, and squeeze the materials.

The impact crusher adopts the impact crushing principle. The material is broken by repeated impact between the plate hammer and the impact plate, so the wear rate of vulnerable parts is higher.

2. Different processing materials

Cone crusher is mainly used for the crushing of hard materials, such as calcite, limestone, granite, pebble, dolomite, bluestone, glass, basalt, iron ore, etc. Cone crusher is mostly used for the large scale stone factory with high output and not high requirement for finished particles.

Impact crusher is mainly used for soft materials, such as pebble, iron ore, limestone, quartz, coal gangue, and construction waste, etc. It is used in building materials, construction, sand aggregate and other small and medium-sized stone factories with strict discharging requirements.

3. Different operating costs

Cone crusher is more expensive and the purchase cost is high, but the service life of wearing parts is long, saving the later maintenance cost, high cost effective.

Impact crusher purchase price is relatively low, but the wearing parts such as the impact plate, hammer head and other parts are easy to wear, need to be replaced frequently, late maintenance and replacement cost is high.

II. Which one has better finished particle size? Cone crusher or impact crusher?

The impact crusher adopts impact crushing principle to achieve more crushing and less grinding of materials. In addition to the crushing function, the impact crusher also has a certain effect of shaping. After its treatment, the sand and stone material particle size is uniform, needle sheet content is low, the gradation is more reasonable, and can be used directly. Customers with strict requirements for grain shape are advised to purchase.

The cone crusher uses extrusion crushing, so that the ore is constantly impacted in the crushing chamber, and the crushing of the ore is realized through extrusion and bending. So the discharge grain shape is not as good as impact crusher, and there are many needles and pieces. It is suitable for the customer who has low requirements for the discharge grain size.

In summary, cone crusher and impact crusher have their own advantages and disadvantages, you should choose based on the actual production needs, the nature of the material, the size of the material, output and other aspects. You can contact our online service  to get machine price, project working program, and delivery time.

to get machine price, project working program, and delivery time.

Previous Article:Difference between Cone Crusher and Impact Crusher

Next Article: The price of 100 Tph Stone Cone Crusher Equipment