How to adjust the Discharging Clearance of Impact Crusher?

author:dahua time:2019-09-16

Impact crusher using impacting force to break material, high crushing rate, product particle shape is cube. Impact crusher is suitable for the crushing of materials with medium hardness, low humidity and viscosity, and small powder content. Such as limestone, gypsum, and activated clay. In the use process, if the crushed material is the same, and the specification of the finished products are also the same, but the quality of the finished products is worse than before, then you need to adjust the discharging clearance of impact crusher.

Note: The discharging clearance adjustment must be carried out in the shutdown state, and there is no material inside the crushing cavity.

Now, let’s talk about how to adjust the discharging clearance of impact crusher.

1. Before leaving the factory, the manufacturer will do rough adjustment for the impact crusher. Adjustment is need in no-load test run or replacement of plate hammer, wear of plate hammer, and the increasement of discharge clearance.

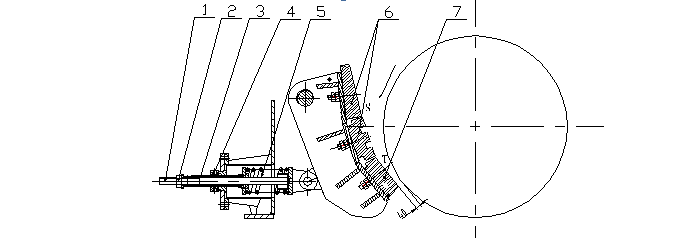

Adjustment of the impact break diagram shown as below, the main parts are:1. Pull rod 2. Small nut 3. Screw rod 4. Tighten nut 5. Spring 6. Impact plate (S section) 7. Wear-resistant plate (T section)

The adjustment impact part has the spring, has the elastic buffer function. When the small piece of unbreakable material enter into the crushing cavity, the spring no.5 compresses, discharge opening is enlarged, unbreakable material is discharged from the crusher body, under the elastic action and restore to the original state.

2. Adjustment of discharging gap

A. When the clearance is increased, open the observation door of the lower frame, loosen the left-handed screw nuts of no. 2 and no. 4, adjust rod no. 3, spring retracted, the clearance between the top of the hammer and the impact plate is increased, the clearance should be smaller than the required clearance size of 10-20mm, and the clearance will be increased by 10-20mm after tightening no. 2 nut. Tighten the nut to achieve the required clearance.

B. Due to the abrasion of plate hammer and liner plate, it needs to adjust to small gaps, open the door of lower frame, loosen the nuts no.2, 4, rightly screw adjusting nut no.3, under the action of spring force, the clearance between impact plate and plate hammer becomes smaller, check the gap size is smaller than the required clearance of 10-20 mm, through tighten nut no.2, the clearance will increase 10-20 mm. Tighten the nut to achieve the required clearance; When replacing the plate hammer or the impact plate, the adjustment clearance should be greater than 30mm.

For example, the existing clearance is 30mm, and the clearance needs to be adjusted to 60mm: a. left screw the nut no.3, the screw back 15-20mm, and then tighten nut no.2 to 10-15mm (adjust according to the spring). Adjust and check the clearance to 60mm, then tighten nut no.4.

Luoyang Dahua is one of the earliest crusher manufacturers in China, with rich design experience and on-site installation and operation experience, if you have any questions in the use process, please visit our website www.lydhcrusher.com, or contact us: [email protected].

Previous Article:What Effect does the Feed Size have on the Crusher?

Next Article: Dry Sand Making VS Wet Sand Making