Introduction of Jaw Crusher Type and Jaw Crusher Technical Parameter

author:dahua time:2020-03-10

With the rapid development of the economy, the demand of ore raw materials is large, the demand of jaw crusher machine is also more. With the continuous upgrading and improvement of science and technology, the technical requirements of jaw crusher are increased, so the types of jaw crusher are more and more. In this text, we will introduce the jaw crusher type and jaw crusher technical parameter.

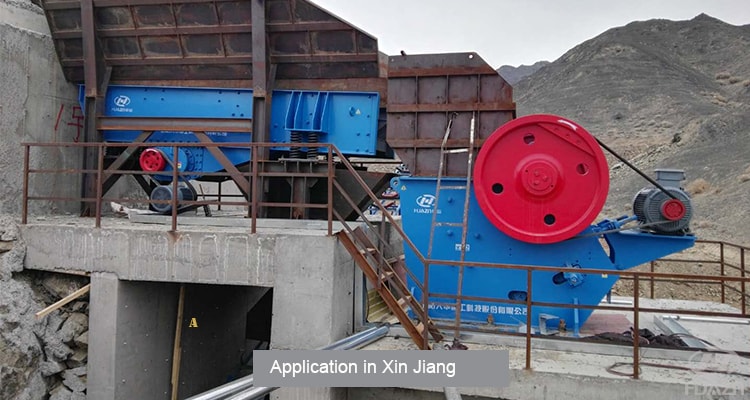

Jaw crusher equipment is common used primary crushing equipment in ore mining, mainly used to deal with all kinds of hard ore, processing materials of many types, can be applied in the fields of mining, building materials, road, railway, water conservancy, chemical industry and other industries of various large block materials crushing, with compressive strength not more than 320mpa.

Jaw crusher type

1. JC series jaw crusher - Optimized motion parameters, wedge block discharge opening adjustment, steel plate toggle plate, oversize bearing design, integral steel frame base

JC series jaw crusher adopts advanced technology, has the features of large crushing ratio, high crushing efficiency, high processing capacity, low operating cost, economical and practical. The feeding size is 720-1360mm, and the production capacity is 50-1500 t/h. It is a best choice for large and medium-sized stone crushing production line.

2. C series jaw crusher - Large crushing force, large crushing ratio, good for maintenance, low failure rate

C series jaw crusher is developed by cooperating with France experts to improve the quality of finished products in the crushing production line. This C series jaw crusher has a better advantage in processing hard materials. It has a complete range of models and can meet the production needs of the majority of users.

3. PE jaw crusher - Deep crushing cavity, high efficiency and energy saving, more convenient adjustment of discharge opening

PE jaw crusher feed particle size is 210-425 mm, the production capacity is 7-380 t/h. The device has more types, this series of jaw crusher is very popular which can satisfy all kinds of large, medium and small stone processing production.

4. Mobile jaw crusher plant - Integrated set of units, wide adaptability, flexible configuration, flexible mobility, easy to enter and exit, with reliable performance, easy for maintenance and operation. Reduce material transportation cost, low site requirement.

Mobile jaw crusher plant developed by Luoyang Dahua is complying with the demand of mining industry development and market demand. The crusher plant can move at any time, and there is little requirement for the working site environment. It is suitable for urban construction waste treatment, the production capacity between 10-650tons. Luoyang Dahua has crawler mobile crusher plant and tyre mobile crusher plant.

Jaw crusher technical parameter

1.Type

The model of the equipment is the main factor that the buyer needs to consider at the initial stage. The size of the model determines the production capacity range of the equipment.

2. Feeding size

General material size determines the size of the feed opening, the larger the broken material, the size of the feed opening will be larger. Large size stone needs to choose large size feed opening.

3. Processing capacity

In the eyes of the buyer, the processing capacity of the equipment is the focus of attention. The production range of hourly processing is one of the reference factors for the selection of users.

4. Motor power

The motor power is determined by combining with the overall size of the equipment. If the equipment is large and the motor power is too small, it cannot be worked. Choosing a reasonable electric power is more conducive to improve the production efficiency of the crusher equipment.

Previous Article:High-performance Horizontal---Three Axle Vibrating Screen

Next Article: Sand Making Process of Cobblestone