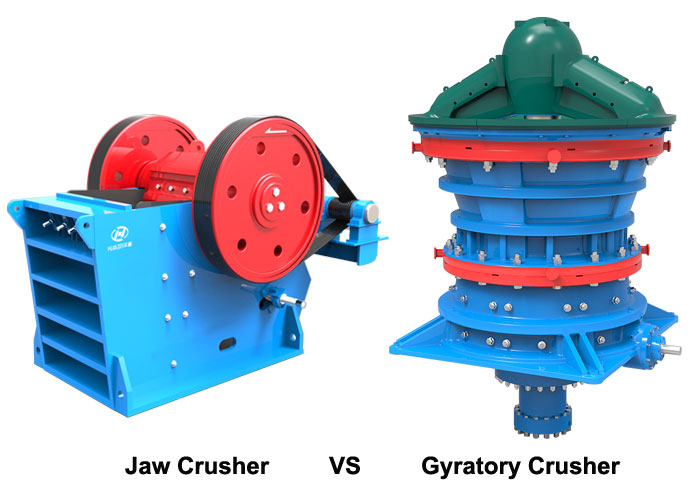

Jaw Crusher VS Gyratory Crusher

author:dahua2 time:2022-03-30

1. Comparison of usage of jaw crusher and gyratory crusher

JC series European jaw crusher is a new generation product successfully developed by finite element analysis method on the basis of decades of traditional jaw crusher design and manufacturing experience. Compared with traditional jaw crushers, JC series jaw crushers pay more attention to details in design and manufacturing, adopt high-strength materials and manufacturing processes, and have higher structural strength, higher equipment reliability and better crushing ratio. Large, higher output, lower comprehensive cost and other advantages.

GC series gyratory crusher is a large-scale crushing machine that uses the gyratory motion of the crushing cone in the inner cone cavity of the shell to squeeze, split and bend the material, and roughly crush ores or rocks of various hardness. The upper end of the main shaft equipped with the crushing cone is supported in the bushing in the middle of the beam, and the lower end is placed in the eccentric hole of the bushing. When the shaft sleeve rotates, the crushing cone makes an eccentric gyratory movement around the center line of the machine. The crushing action is continuous, so the working efficiency is higher than that of the jaw crusher.

Generally, gyratory crushers are mostly used in large concentrators. Because of their large size and large output, gyratory crushers are widely used in metallurgy, building materials, chemical production, mineral crushing and other projects, so they are mainly used in the first stage. It is a typical coarse crushing equipment for coarsely crushing materials of various hardness, and some concentrators also use large jaw crushers as coarse crushing.

In general, small concentrators and quarries, especially when dealing with viscous materials, mostly use jaw crushers as the primary crushing task in the first stage.

2. Comparison of performance advantages of gyratory crusher and jaw crusher

The outstanding advantage of the gyratory crusher is that the crushing wall is large, which can reach -9.5, and sometimes it can be as high as 13.5. The production efficiency is high, and the work is relatively stable. Either side can feed ore and can be crowded with ore. The particle size of the crushed product is uniform.

Jaw crusher is intermittent crushing, and its structure is relatively simple, so it has the advantages of low manufacturing cost, reliable operation, convenient maintenance and repair, and it is not easy to block ores with high water viscosity and high viscosity.

3. Comparison of the disadvantages of gyratory crusher and jaw crusher

The disadvantage of the gyratory crusher is that the structure is complex and the fuselage is high, so the cost of a single equipment is high and a high workshop is required, the machine is heavy, it is not convenient to handle, it is not suitable for crushing viscous ore, and the maintenance work is complicated.

The main disadvantages of jaw crusher are that compared with gyratory crushing, the productivity is low, the power consumption is large, the vibration is large, the crushing ratio is small, the product particle size is not uniform enough, and it cannot be crowded to feed the ore.

The above are some basic comparisons between gyratory crushers and jaw crushers. When selecting head crushing or coarse crushing equipment, a comprehensive analysis should be carried out according to different situations, such as feeders, crushers, sand making machines, screening machines, The mechanical equipment and production efficiency of mining manufacturers such as conveyors should be considered in a balanced manner. Whether it is a gyratory crusher or a jaw crusher, it can meet the requirements. At the same time, it can be used according to the process flow. Medium and fine crushers, investment, infrastructure, etc. Various measures are taken to determine which crusher to be used.

Previous Article:No Information

Next Article: Advantages of Dry Sand Production Line