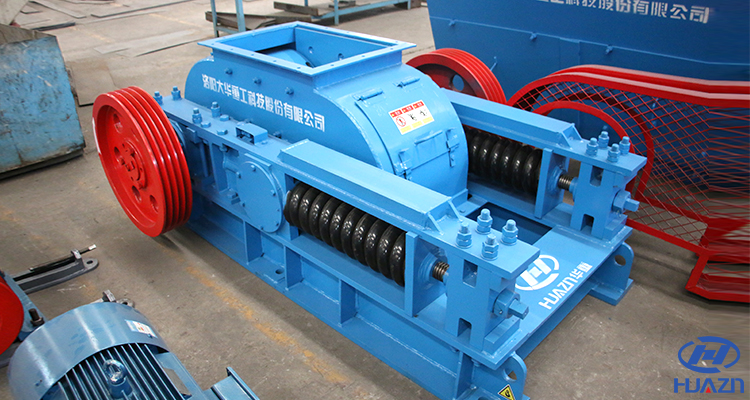

Roller Crusher for Stone Sand Making

author:dahua time:2021-04-20

Double roller crusher is known as toothed roll crusher, or roll crusher. It has large crushing ratio (5-8), simple structure, low noise, and easy maintenance. Double roller crusher is suitable for medium hardness brittle material crushing in the field of sinter, coal, cement, silicate, glass, ceramics and other industries, it also mainly used for medium and fine crushing of ore.

Advantages of double roller crusher

1. Compared with other types of crushers, this series of crusher has a large crushing ratio and no requirement for moisture of crushing materials. It has the feature of non-sticking, non-blocking, less crushing, low noise, small vibration, less dust, low energy consumption, small floor space, simple and convenient maintenance, etc.

2. Equipped with hydraulic automatic retreat device, which can effectively prevent the damage of iron to the tooth roller and the harm of wood and flexible objects to the normal work of the tooth roller.

3. Equipped with intelligent cleaning device, can automatically remove the adhesive material on the crusher cavity wall at the working intervals.

4. Adopt mechanical, electrical, hydraulic and other multiple protection devices and interlocking devices to effectively protect the motor, crusher and the whole system.

5. The product has become the preferred equipment for thermal power plants to replace imported crushing equipment with the advantages of high efficiency, energy saving and environmental protection.

Parameter of double roller crusher

|

Type

|

Specification

|

Feed Size(mm)

|

Discharge Size(mm)

|

Capacity(m3/h)

|

Power

(kw)

|

Outline Dimension

(mm)

|

|

StrongDouble-roller crusher

|

2PGQ 610×400

|

<36

|

2-9

|

3-9

|

15×2

|

2085×3090×802

|

|

2PGQ 750×500

|

<40

|

2-10

|

3-16

|

18.5×2

|

2344×1900×1605

|

|

|

2PGQ 750×700

|

<40

|

2-10

|

5-25

|

22×2

|

2344×2318×1605

|

|

|

2PGQ 900×500

|

<40

|

2-10

|

5-26

|

22×2

|

2750×1956×1662

|

|

|

2PGQ 900×900

|

<40

|

2-10

|

11-45

|

~37×2

|

2750×2356×1662

|

|

|

2PGQ 900×1200

|

<40

|

3-10

|

15-60

|

~55×2

|

2750×2480×2065

|

|

|

2PGY 1200×1000

|

<40

|

3-12

|

15-60

|

~45×2

|

3476×2894×2200

|

|

|

2PGY 1200×1200

|

<40

|

2-12

|

18-68

|

~75×2

|

3476×3117×2200

|

|

|

Four-roller crusher

|

4PG750×500

|

<30

|

2-4

|

3-10

|

18.5+11/17

|

2760×2105×2650

|

|

4PG900×700

|

40-100

|

2-10

|

11-18

|

30+15/24

|

3150×2450×2747

|

|

|

4PG900×900

|

40-100

|

2-10

|

14-24

|

45+24/37

|

3160×2650×2747

|

|

|

4PGY1200×1000

|

20-40

|

3-10

|

43-68

|

90+40/55

|

4138×3300×3650

|

|

|

Double teeth roller crusher

|

2PGC450×500

|

100-200

|

25-100

|

20-55

|

<11

|

2360×2206×916

|

|

2PGC600×750

|

300-600

|

50-125

|

60-125

|

22

|

2635×2850×1025

|

|

|

2PGC900×900

|

<800

|

75-150

|

100-180

|

30

|

3710×2300×1394

|

|

|

2PGC1000×800

|

150-400

|

5-150

|

30-150

|

55

|

3480×2300×1360

|

|

|

2PGC1200×1500

|

<200

|

<40

|

100-160

|

2×55

|

3370×3500×1945

|

|

|

2PGC1200×1500

|

<150

|

<20

|

450-600

|

2×250

|

5890×4220×2370

|

Luoyang Dahua can provide unit crusher machine, mill machine, sand making machine, and also can provide complete solution for the stone production line, EPC project. From before sale to after sale, the company has professional engineers to take in charge. For more information, please contact our online service or send email to [email protected].