Several Reasons for the Loosening of Cone Crusher Adjusting Ring

author:dahua time:2021-05-04

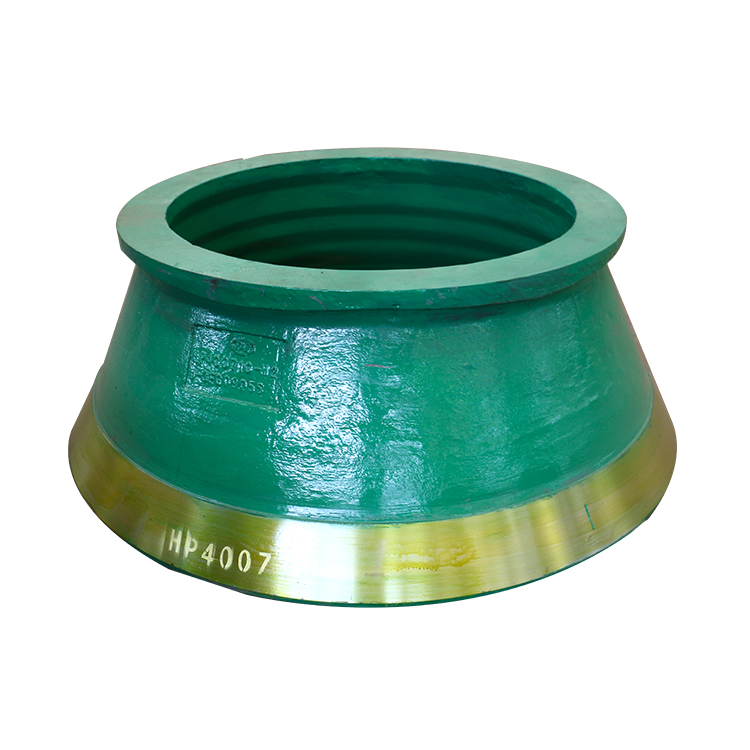

In the cone crusher, the adjusting device is used to adjust the size of the crusher outlet to control the particle size of the discharged materials. It mainly comprises a support sleeve, adjusting cap (dust cover), adjusting ring and locking cylinder, etc. The adjusting ring is an important component, which is connected with the fixed cone and the fixing pin of the main frame, etc., and plays a huge role in the normal operation of the crusher equipment. This article will share with you the five reasons and solutions of the loosening of the cone crusher adjustment ring.

Reasons for the loosening of cone crusher adjusting ring

1. The adjustment ring is a dynamic cone, its external cone surface has serrated threads. When the support sleeve, the thread of the adjustment sleeve is worn, it will cause the adjustment ring loose.

2. Before starting the cone crusher machine, it is necessary to check all parts of the cone crusher. Fasten or replace loose and damaged areas immediately. If the adjustment cap of the device is not locked, it will cause the loosening of the adjustment ring.

3. When the cone crusher is at work, due to the needs of production, the crusher outlet needs to be adjusted. If errors occur in the process of adjustment, the crusher outlet will be too large or too small, resulting in the loosening of the adjustment ring.

4. The mantle concave are too thick, resulting in the loosening of the adjusting ring.

5. When the locking rod of the adjusting cap is broken, the cone crusher is still in working state, resulting in the loosening of the adjusting ring.

Solution for the loosening of the cone crusher adjustment ring

1. When the thread of the support sleeve and the adjustment sleeve is worn, it is necessary to repair or replace it according to the wear condition, so as to reduce the loosening of the adjustment ring.

2. Before starting the cone crusher machine, fully check all parts of the machine. If the adjusting cap is found to be loose, it should be locked in time.

3. Adjust the crusher outlet, so that it is in a normal state.

4. The mantle and concave are too thick, which his will cause the adjustment cap fail to contact the top of the support sleeve. It is necessary to modify or replace the mantle and concave of appropriate thickness, or to install a special adjusting cap washer.

5. If the locking rod of the adjusting cap has been broken, it should be replaced in time.

Summary: in the process of maintenance of cone crusher, the maintenance of adjusting ring is a necessary link, when the phenomenon of loosening or damage occurs, targeted measures should be taken to ensure the safe and stable operation of the cone crusher equipment.

Previous Article:Ball Mill For Sale

Next Article: What is the Reason for the Strong Vibration of Hammer Crusher?