Stone Crusher Machine Manufacturers teach you how to prolong the Life of Sand Making Machine

author:dahua time:2020-08-26

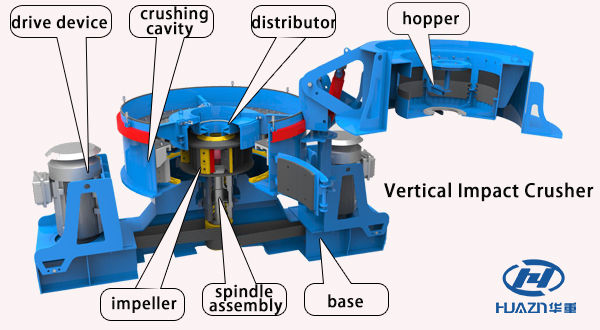

To prolong the service life of sand making machine, we must first understand the key parts of sand making machine. It includes bearing, impact block, rotor and impeller, etc. Effectively play the role of key parts, prolong the service life of the parts, can effectively increase the service life of sand making machine. This requires us to operate in accordance with the rules and regulations, and also know how to maintain and replace.

1. Bearing

The role of the bearing is to fix the hammer head, the plate hammer or the impact plate, so that it has good adaptability with the motor. Since the sand making machine needs to be connected with a rotating device, and the bearing is an essential part, it is necessary to add proper lubrication oil to the bearing regularly to reduce the wear between parts, thus effectively increasing the service life of the sand making machine.

2. Rotor

The main role of the rotor is to drive the high speed rotation of the sand making machine. In the process of mechanical sand production, the inner, top and bottom edges of the rotor are easy to wear. The main reason is the impact and friction between materials, especially smaller particle size, strong abrasive, stone moisture and so on. If the transfer is unbalance in operation, it will produce vibration, so that the rotor bearing and rotor wear.

3. Impact block

The impact block is a part of sand making machine with severe wear. The main reasons are improper selection of impact block material, inappropriate material nature, unreasonable structural parameters, and unreasonable clearance between impact block and impacting plate. Each type of sand making machine has corresponding accessories. If the hardness of the material exceeds the specification of sand making machine, the friction between the material and the impact block will be increased, causing the impact block to be worn.

4. Impeller

Make sure that there is no residual foreign matter in the impeller when the sand machine is running, otherwise it may cause the impeller to get stuck or burn down the motor. If the sand making machine is stuck due to too fast feeding speed and too big and hard material, the sand making machine should be shut down in time, and the machine should be started up after the material is cleaned up, and the feeding speed and material size should be adjusted at the same time.

In addition to pay attention to the key parts of sand making machine, after production we should pay attention to the daily inspection. Carry out comprehensive inspection on the equipment, especially the places prone to failure, and carry out maintenance work of sand making machine regularly.

Luoyang Dahua is specialized in the production of jaw crusher, impact crusher, cone crusher, sand making machine, mobile crushing station and provide solutions for stone and sand crushing production line. With a professional R & D team, a strong after-sales team, from the equipment selection, site investigation, to equipment manufacturing, installation, commissioning, and delivering, Luoyang Dahua professional engineers will be responsible for. Welcome to contact us to get latest quotation. Email: [email protected]

Previous Article:Can PLS Sand Making Machine be configured as Mobile Sand Making Crusher?

Next Article: What is the Concrete Waste Crushing Equipment?