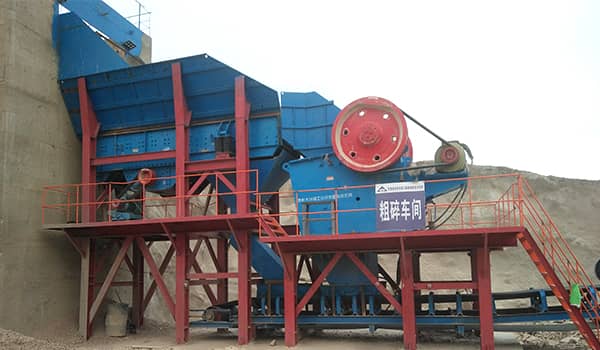

Stone Crusher Machine

author:dahua time:2019-09-24

There are various kinds of stone crusher machine, jaw crusher, impact crusher, cone crusher, sand making machine, and mill machine, sand washer as well as auxiliary equipment. Stone crushers can meet the requirements of different types of stone crushing production line with different materials, different product granularity, and different productivity through a variety of configuration combination. It is widely applied in mining, metallurgy, building materials, water conservancy, hydropower, highway construction and other fields. Next, we introduce the different types of stone crusher.

Stone crusher - jaw crusher. Jaw crusher is the primary crushing equipment, is the first crusher in the stone crushing line. It has the feature of simple operation, large feeding opening, and high output. The materials are fed to jaw crusher through vibrating feeder, the crushed materials are transported to impact crusher or cone crusher for medium and fine crushing. The crushing cavity of jaw crusher composed of movable jaw plate and fixed jaw plate. When the crusher works, movable jaw plate does reciprocating motion to crush the materials through squeezing force. So jaw crusher has simple structure, stable operation, the small type can be used on mobile crushing plant for construction waste treatment.

Stone crusher - impact crusher. Impact crusher uses impacting force to crush materials. It has unique three crushing cavity, after the materials enter into the crushing cavity, the stones are broken by impacting plate, hammer plate and mutual striking. Impact crusher is suitable for the crushing of medium hard materials with low viscosity, in case to block the discharging opening. Although the price is slightly lower, in the selection of crusher, should according to the hardness of the broken material, viscosity, water content and other characteristics. If the broken material is very hard, it will accelerate the impact plate abrasion, shorten the service life, need to replace the impact plate frequently, and increase maintenance costs.

Stone crusher - hydraulic cone crusher. Hydraulic cone crusher has single cylinder hydraulic cone crusher and multi-cylinder hydraulic cone crusher. When the single cylinder hydraulic cone crusher crushes soft ore and weathered ore, its advantage is large through capacity, in the crushing of hard, and high hard ore, multi-cylinder hydraulic cone crusher is more suitable. Multi-cylinder hydraulic cone crusher has a high content of fine particles, and a good effect of fine crushing and laminating. Single-cylinder hydraulic cone crusher has good medium crushing effect and a large amount of throughput. In terms of maintenance, single cylinder hydraulic cone crusher has simple structure, low failure rate, low production cost and stronger operation stability.

Stone crusher - sand making machine. Sand making machine is also called vertical impact crusher (VSI sand making machine), it combines the function of crushing and sand making. "Stone beat stone" sand machine products that less than 5mm, the yield is 28%-35%, and the shape is square, the energy consumption is 1.0~2.5 KWH/ton, processing materials are not subject to material characteristic and humidity restrictions. The crushing mode "stone beat iron" , with larger crushing ratio, are suitable for artificial sand making. Dahua PLS sand making machine is more suitable for the fine crushing of medium hardness materials, and PFL complex crusher is used for the fine crushing of soft materials.

Inspection of stone crusher

No matter the crusher is running normally or not, it is necessary to take the regular maintenance and inspection in order to wipe out the potential problems. During inspection process, the machine must be completely shut down for maintenance. Be sure to check the wearing parts when checking the machine. If the wearing parts reach the maximum worn degrees, should be replaced immediately so as to reduce the abrasion of machine cover and extend the machine service life.

Check the temperature of the bearing and the abrasion situation in the process of overhaul, and handle the problem in time. The final inspection aspect is to check whether the lubrication oil is sufficient or not. Long-term lack of lubrication oil will lead the main parts of crusher machine being damaged, and directly affect the machine output or even damage the machine cover. Regular maintenance and inspection can reduce the fault rate, improve the working efficiency, and prolong the service life.

Previous Article:The Prospect of Jaw Crusher

Next Article: Investment Capability of Mobile Construction Waste Crusher