Three motion states of Grinding Balls in Dry Ball Mill

author:dahua time:2020-03-13

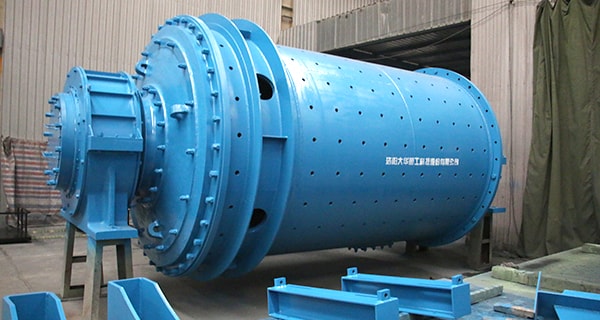

The dry ball mill has the advantages of simple structure, wide applicability and convenient operation. Ball mill adopts drum ball grinding tank, the tank is loaded with different sizes of grinding balls, the loading quantity is 1/4-1/2 of the effective capacity of ball grinding tank.

When grinding a dry ball mill, the filling rate of the ball is within a reasonable range and the roller mill is running at different speeds, the ball may appear in three basic motion states in the tank.

1. "Turnover status": Because the speed is too high, the grinding ball is affected by centrifugal force and rotates close to the wall of the ball grinding tank. The grinding ball forms a ring on the inner wall of the tank. The grinding ball cannot collide and squeeze the materials.

2. "Drop state": If the rotation speed is too low, the grinding ball and the material will slide down when they rotate to 30°-50° with the tank wall. Although there is a partial grinding effect on the material, there is no impact collision, and the grinding energy is small, resulting in poor grinding efficiency.

3. "Throw state": With the proper dry ball mill speed, under the combined action of centrifugal force and friction force, the grinding ball moves with the tank wall to the corresponding height, leaving the tank wall and falling freely along the parabolic track. The falling grinding ball collides and grinds the material to make it pulverize.

Luoyang Dahua ball mill, rod mill and tube mill are widely in the field of mining, nonferrous metal mining, non metal mine, construction material, and power industry. Please contact our online service or send email to [email protected] to get more information and latest quotation.