What Kind of Crusher is Good for Crushing Wet Material?

author:dahua time:2020-12-17

In the aspect of wet material crushing, it can be divided into wet coal crushing and other material crushing. Here we talk about wet coal crushing. Wet coal crusher is used for crushing dry coal or the one with moisture containing more than 15%, ore, rock, and other medium hardness materials in power, scientific research and other industries and departments. The output of wet coal crusher can be adjusted independently in production, and the output granularity is symmetrical, the production efficiency is high.

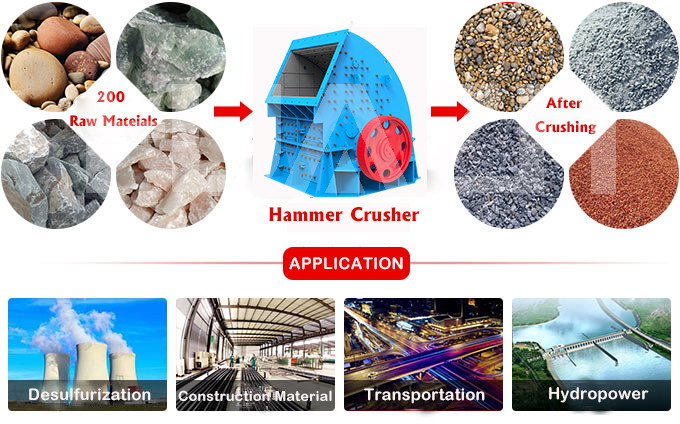

The hammer crusher of Luoyang Dahua can be used for crushing wet coal. The hammer crusher is mainly used for medium hard, brittle and water-bearing materials.

PCZ series hammer crusher

Feed size: ≤1500mm

Production capacity: 250~2000t/h

PC series hammer crusher

Feed size: < 350mm

Production capacity: 0.3~156t/h

PCD series single stage hammer crusher

Feed size: 600~1900mm

Production capacity: 80~1000t/h

In addition to wet coal, what crusher is better for other wet hard rock material? Take hard rock materials like pebbles, bluestones, or granite for example. These materials with high hardness, but less moisture content, so we can use the common jaw crusher, cone crusher or impact crusher. If the materials content more moisture, you can take the first drying and then crushing production process. After the wet material is dried, it is broken by the crushers.

Wet material processing should consider the characteristics of the material, water content and other factors to determine which crusher to use. But most of the time, we can finish the production with a regular crusher.

JC series jaw crusher

Maximum feed size: 430~1360mm

Production capacity: 50~1500t/h

PFQ series strong vortex impact crusher

Feed size: 150~600mm

Production capacity: 50~1200t/h

HPY series multi-cylinder hydraulic cone crusher

Feed size: 25~353mm

Production capacity: 60~1100t/h

Luoyang Dahua has more than 30 years experience in manufacturing crusher machine, grinding machine, sand washer, mobile crusher plant. From machine design to site installation and training, the professional engineer will be assigned to take in charge. If you want to know more about our company, please visit www.lydhcrusher.com or send email to [email protected].

Previous Article:What Materials can be crushed by Roller Crusher?

Next Article: Mechanical Sand Production Process and Crushing Equipment Technical Optimization