What is the Difference between Jaw Crusher and Gyratory Crusher, and which Effect is Better?

author:dahua time:2021-02-23

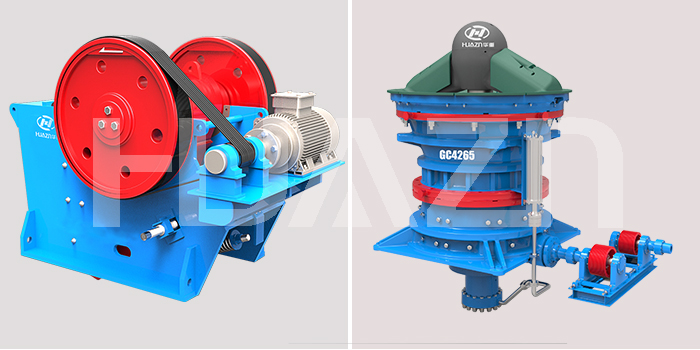

Jaw crusher and gyratory crusher are extrusion crushing equipment, suitable for coarse crushing of ore materials with higher hardness. Jaw crusher is widely used because of high cost performance. In fact, there are also big differences between jaw crusher and gyratory crusher in other aspects. After reading this text, you should have your own answer to "which effect is better".

1. Different processing capacity

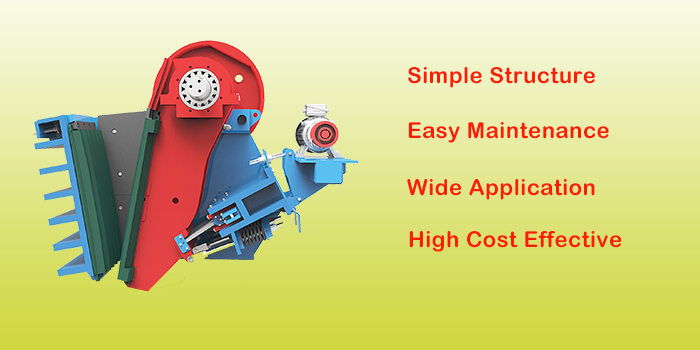

(1) The jaw crusher adopts intermittent crushing, the structure is relatively simple, the cost will be lower, the maintenance is more convenient, and there will be no blockage problem when dealing with large moisture materials.

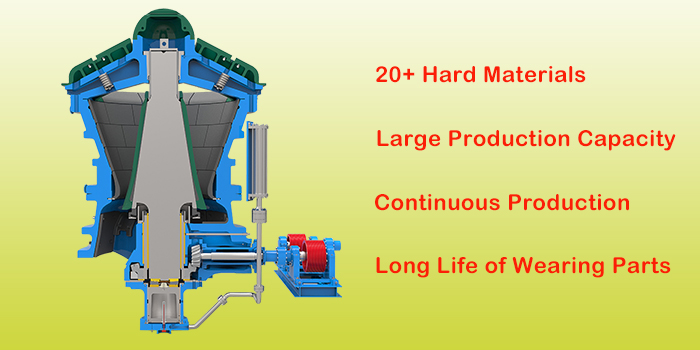

(2) The prominent advantage of the gyratory crusher is that the crushing ratio is large, the production efficiency is high, the production can be continuous, the work is stable, and the feeding hopper can be full of material.

2. Different shape and structure

(1) Jaw crusher has the advantages of simple structure, low manufacturing cost, small machine height, easy configuration, convenient maintenance and so on.

(2) The gyratory crusher has complex structure, high fuselage and large volume, which requires a higher workshop. The base construction investment is large, the machine is heavy and inconvenient to carry.

3. The particle size of feeding and discharging material is different

(1) The jaw crusher feeding particle size requirements are strict, the size of the raw material should be within the specified range. In addition, after crushing, the shape is mostly in flat, sharp or triangular flat and elongated particle, the content of more than 20%.

(2) The feeding particle size of the gyrotary crusher is larger, and the discharging particle size is smaller and more uniform, and the content of needle-like particles in the discharging is less, generally less than 10%. The raw material can be fed directly into the feed port from the harvester without setting up the feeder.

4. The life of wear-resisting parts is different

(1) The jaw crusher mainly uses the extrusion action of the movable jaw plate and the static jaw plate to complete the crushing. The direct contact surface of the jaw plate and the material is larger, the wear is faster, and the maintenance is large.

(2) The gyratory crusher adopts the principle of lamination crushing. The crushing process is carried out continuously along the circular crushing cavity, and the service life of wear-resisting parts is longer than that of jaw crusher.

5. Different energy consumption

(1) Jaw crusher adopts non-continuous extrusion crushing, the capacity is small, in addition, the particle size of the crushed material is uneven, the coarse material proportion is large, and the energy consumption of the equipment is increased.

(2) The average energy consumption of medium gyratory crusher is much lower than that of large and medium jaw crusher.

6. Maintenance cycle and cost are different

(1) The daily operation and maintenance of the jaw crusher is simpler than the gyrotary crusher.

(2) The equipment price of the gyratory crusher is high, but its operation cost is low and the maintenance interval is long.

7. Applicable materials and site are different

(1) Jaw crusher can handle the ore with high moisture and large viscosity, and is not easy to block. Generally small concentrators and quarries use jaw crusher as coarse crushing.

(2) Gyratory crusher is mainly used for coarse crushing of all kinds of hardness materials, but should not be broken viscous ore, general large concentrator uses gtratory crusher.

Conclusion: Which effect is better, jaw crusher or gyratory crusher?

In this paper, it is not difficult to identify the advantages and limitations of the two crushers. According to experience, if a jaw crusher machine can meet the production requirements, the jaw crusher is used; If two jaw crushers are needed, one gyratory crusher can be considered to simplify the production process. In addition, many factors such as infrastructure construction and environmental protection can be considered comprehensively.

Luoyang Dahua has more than 30 years experience in manufacturing crusher machine, sand washer, mill machine and also can provide complete solution for the stone production line. If you want to know more information about our company or the products, please visit: www.lydhcrusher.com or contact our online service .

.

Previous Article:How to clean the Crusher correctly?

Next Article: How to configure Crushing Equipment for 2000t/h Sand Aggregate Production Line?