What is work flow of stone crushing and screening production line?

author:dahua time:2020-03-03

The stone crushing and screening production line is mainly composed of vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor and centralized electronic control equipment. The designed output is generally 30-1000t/h. In order to meet different processing needs of customers, it can be equipped with cone crusher, VSI sand making machine and dust removal equipment. It is widely used in hydropower, building materials, highways, urban construction and other industries. The crushing and screening production line can be used for crushing hard limestone, granite, basalt, river pebble and other materials. It is especially suitable for special construction fields such as surface material of expressway, gravel of high-grade highway, sand and gravel aggregate of high-speed railway passenger, sand and gravel of hydropower station.

Working principle of stone crushing and screening production line

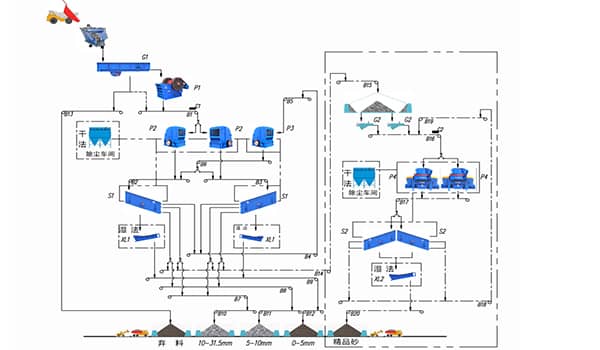

The material is evenly sent to the jaw crusher through the vibrating feeder for primary crushing. The coarse broken material is sent to the impact crusher (or cone crusher) by the belt conveyor for the secondary crushing (fine crushing). The finely crushed materials are sent to the circular vibrating screen by the belt conveyor, through which the finished stone materials of different specifications are sorted out. The materials that do not meet the requirements are returned to the impact crusher (or cone crusher) by the belt conveyor for re-crushing. In order to protect the environment, auxiliary dust removal equipment can be equipped.

Features of stone crushing and screening production line

1. Stone crushing and screening production line has high degree of automation, large crushing ratio, high production efficiency and large handling capacity. The products after crushing are cubic, low needle-like content, no internal cracks and high compressive strength.

2. The equipment is easy to maintain and the wearing parts are made of the new high-strength wear-resistant materials, with small loss and long service life, which can bring considerable economic benefits to customers.

3. The designed stone crushing production line has been successfully applied to the crushing and processing of limestone, basaltic stone, granite, pebble and other rocks, and the finished products are completely reached the standard of GB14685-2001, providing qualified aggregate for the industries such as highway, railway, water conservancy and concrete mixing plant.

Luoyang Dahua is a professional stone crushing production line equipment manufacturers, can supply customized design production line to meet different customer needs. The equipment configuration of stone material production line is mainly determined according to the specifications of stone material, the output and the use of stone material. We provide comprehensive before service, during and after sale service, according to the customer production site to configure the process, and strive to achieve a reasonable and economic production line for customers. At present, we have provided products and technical support for thousands of customers at home and abroad. Welcome to contact us for the latest quotation. Email: lydhchina@huazn.com

Previous Article:Analysis of Common Failures and Causes of Cone Crusher

Next Article: What Kind of Crusher is more Cost Effective for Basalt Crushing?