Introduction, feature, structure of Autogenous Mill

author:dahua time:2018-11-12

Autogenous mill is a kind of ore grinding equipment with the function of crushing and powder grinding. It used the grinded material as a medium through mutual striking and grinding to finish crushing. Autogenuo grinding feeds the large ore with the maximum size up to 300mm - 500mm directly into the autogenus mill. Due to the different blocks of ore driven in the grinding equipment generate the similar movement as it did in ball mill, in this way, the ores in mill can be crushed by grinding and strongly striking with each other.

The most important feature of autogenous mill is to feed the raw material from quarry or the primary crushed ore into the grinder. Normally the materials are fed into the rod mill according to the granularity ratio. The autogenous mill can grind the material to -0.0744mm. with the content of 20%-50% of the total output. The crushing ratio can reach 4000-5000, which is more than ten times higher than the ball and rod mill.

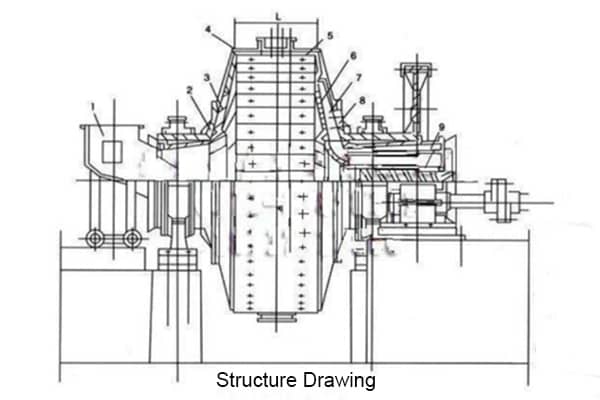

The autogenous mill consists of main bearing, barrel body, drive parts, cylinder screen, main motor, low speed driven device, jacking device, lubrication system and electrical control system. See the following figure:

The structure feature:

(1) Big diameter, short length, shaped like a flat drum. The ratio between length and diameter (L/D) is around 0.3 – 0.35. The shorter barrel of self-grinder is to prevent ore "segregation" in the process of grinding so as to reduce the grinding efficiency.

(2) The big diameter of hollow pivot on both ends of barrel body can match the fed ore size.

(3) The liner plate of wet type autogenous mill is concaved in the center. This is to make the material centralized piled, so as to prevent the material particle size separation

Previous Article:Maintenance and Overhaul of Ball Mill

Next Article: Global Construction Aggregates Market worth over US$565.8bn by end of 2026