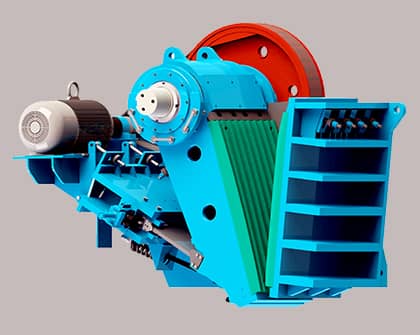

JC Series Jaw Crusher

Description

Features

1. The structure design is suitable for crushing different kinds of minerals.

2. Optimal design of kinematics parameter and crushing chamber increase processing capacity and crushing performance.

3. The wedge adjustment for CSS achieves infinite adjustment, which is quick and convenient.

4. The bearing design ensures the big loading capacity and reliable operation of jaw crusher.

5. The design of toggle plate increases the stroke of lower chamber and processing capacity.

6. The integrated design of the motor base together with the main frame saves the installation space.

7. In order to increase JC jaw crusher crushing performance, various jaw plate tooth-shapes are suitable for different crushing materials.

Parameter

| Model | Feed Opening Size(mm) | Max. Feed Size(mm) | Discharge Opening Size(mm)/Capacity(t/h) | Power(kw) | ||||||||||||||

| 40 | 50 | 60 | 70 | 80 | 90 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 | 300 | ||||

| JC80 | 800×510 | 430 | 50 | 55 | 80 | 90 | 110 | 120 | 135 | 170 | 200 | 240 | 75 | |||||

| 70 | 85 | 100 | 125 | 145 | 170 | 185 | 240 | 280 | 330 | |||||||||

| JC90 | 900×600 | 500 | 80 | 100 | 120 | 140 | 160 | 180 | 210 | 260 | 300 | 90 | ||||||

| 110 | 120 | 140 | 170 | 200 | 220 | 280 | 330 | 360 | ||||||||||

| JC100 | 1000×760 | 640 | 130 | 160 | 180 | 200 | 235 | 280 | 330 | 390 | 110 | |||||||

| 190 | 200 | 225 | 250 | 310 | 370 | 420 | 520 | |||||||||||

| JC110 | 1100×850 | 720 | 180 | 200 | 220 | 245 | 300 | 350 | 400 | 460 | 110 | |||||||

| 240 | 265 | 295 | 320 | 385 | 455 | 520 | 590 | |||||||||||

| JC125 | 1250×950 | 810 | 270 | 325 | 385 | 445 | 500 | 560 | 620 | 160 | ||||||||

| 360 | 430 | 505 | 580 | 650 | 725 | 800 | ||||||||||||

| JC130 | 1250×1100 | 940 | 330 | 360 | 440 | 500 | 555 | 600 | 670 | 730 | 185 | |||||||

| 400 | 450 | 530 | 610 | 700 | 780 | 850 | 900 | |||||||||||

| JC140 | 1400×1070 | 910 | 380 | 465 | 530 | 580 | 650 | 710 | 760 | 200 | ||||||||

| 470 | 555 | 640 | 725 | 815 | 900 | 985 | ||||||||||||

| JC160 | 1600×1200 | 1020 | 490 | 550 | 635 | 710 | 780 | 855 | 930 | 250 | ||||||||

| 640 | 730 | 825 | 920 | 1010 | 1105 | 1200 | ||||||||||||

| JC1613 | 1600×1300 | 1110 | 530 | 600 | 680 | 750 | 850 | 910 | 960 | 315 | ||||||||

| 680 | 760 | 870 | 960 | 1100 | 1200 | 1300 | ||||||||||||

| JC2012 | 2000×1200 | 1020 | 600 | 670 | 750 | 830 | 950 | 1050 | 1150 | 355 | ||||||||

| 730 | 900 | 1030 | 1150 | 1220 | 1300 | 1400 | ||||||||||||

| JC180 | 1800×1500 | 1300 | 700 | 810 | 930 | 1000 | 1080 | 1200 | 355 | |||||||||

| 1000 | 1150 | 1300 | 1450 | 1600 | 1800 | |||||||||||||

| JC200 | 2000×1500 | 1300 | 750 | 860 | 960 | 1050 | 1150 | 1300 | 400 | |||||||||

| 1100 | 1280 | 1500 | 1650 | 1850 | 2000 | |||||||||||||

Remarks:

1.The capacity listed from the table is the corresponding parameters to crush the rock with the loose density of 1.6t/m³ (a feed material with an average specific gravity of 2.7t/m³).

2.The processing capacity shall be changed according to the different materials and different feeding.

3.The CSS refers to Closed Side Setting. The measuring method will be decided by the tooth profile of the jaw plates.

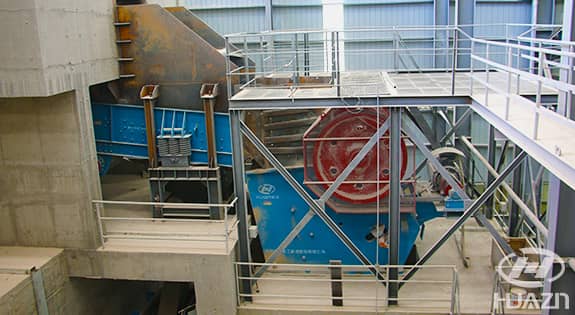

Machine Photo

Customer Cases

2000t/h Limestone Production at Mengzi Country, Yunnan Province

The main equipments: ZSW1860 vibrating screen, JC140 jaw crusher, PFQ1520 impact crusher, 3YK3280 vibrating screen, PFL1750 complex crusher, 2YK3073 vibrating screen.

600 t/h Limestone Production Line at Shanxi Province

The main equipments: ZSW1860 vibrating feeder, JC140 jaw crusher, DHKS6016 jaw crusher, vibrating screen and electrical control system.

Get Solution & Price Right Now!

leave your message here, we'll send you an Email immediately.

- E-mail: [email protected]

- Add.: No.280, Guanlin Road, Luoyang, Henan, China

- Tel.: +86-379-62669995